Bean-to-Bar Chocolate Making

The Sweet Journey

At our chocolate factory, we prioritize the meticulous process of transforming sun-dried beans into delectable chocolate bars. Once the beans have been carefully sun-dried to achieve the desired moisture level, they are subjected to a controlled roasting process.

Our expert chocolatiers ensure that the beans are roasted at the perfect temperature to unlock their rich flavors and aromas. After roasting, the beans are allowed to cool, preserving their quality and allowing the complex flavors to develop further. Once cooled, the beans are cracked and winnowed using advanced machinery, which separates the cocoa nibs from the husks.

Good Things Take Time

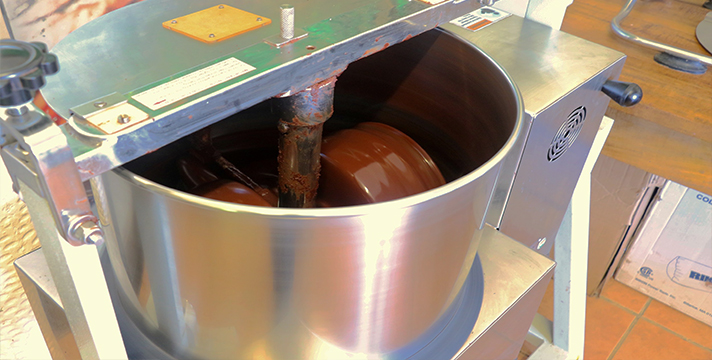

Our skilled team then hand-sorts the cracked beans to remove any remaining cocoa husks that may have escaped the machines, ensuring that only the highest-quality cocoa nibs are used in our chocolate-making process. The hand-selected cocoa nibs are then added to a melange, where they undergo a process of grinding and refining to transform them into smooth and luscious chocolate.

To achieve the perfect texture and taste, our experienced chocolatiers carefully hand-temper the chocolate, a crucial step that involves precisely controlling the temperature to create a stable crystalline structure. Finally, our chocolate bars are individually hand-packaged, ensuring that each bar receives the attention it deserves and maintaining the utmost quality from production to presentation.